|

NINGBO LEC MAGNETIC TECHNOLOGY CO.,LTD.

|

Plastic bonded neodymium magnets

| Price: | 0.01 USD |

| Payment Terms: | T/T,L/C,D/A,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Plastic bonded neodymium magnets,isotropic compression molded rare earth neodymium ring magnet for Automobile Electric Motor Printers and Sensors.BNP8

Generally, the Plastic bonded neodymium magnetis produced by molding compression of the compound ndfeb alloy powder with epoxy resin, also it can be made by injection or extrusion from NdFeB alloy powder mixed with plastic.

The characteristics of the Plastic bonded neodymium magnet are as follows:

1,Higher Magnet Property: the magnet property of pressing bonded NdFeB magnet is between that of sintered NdFeB and ferrite, and with good consistency and stability.

2,Large Freeness of Product Shapes and High Precision of Dimension: the magnet shape and dimension are decided by the tooling, like ring, segment, block, etc., without further sintering and mechanical machining processes.

3,Good Corrosion Resistance: after electrodeposited or through other special treatments, it can be used under normal or unfavorable environment conditions for a long time.

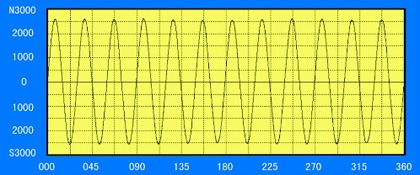

4,Diverse magnetization: Multi-pole magnetization and screw angle magnetization are available, and the field distribution could be square, sinusoid and so on.

5,It has high production efficiency, suitable for mass production.The pressing bonded NdFeB magnet is mainly used for all kinds of micro–miniature motors, such as spindle motor, stepping motor, synchronous motor, DC motor and brushless DC motor. It can replace sintered NdFeB magnet and ferrite, making motor assembling simpler and more reliable, reducing costs and improving efficiency.

The performance of plastic bonded ndfeb magnets

BNP-3 | BNP-6 | BNP-8 | BNP-8SR | BNP-9H | BNP-10 | BNP-11 | BNP-12L | |

Br (mT) | 450-510 | 590-650 | 620-670 | 620-66 | 650-700 | 680-720 | 700-740 | 730-770 |

Br (Gs) | 4500-5100 | 5900-6500 | 6200-6700 | 6200-6600 | 6500-4000 | 6800-7200 | 7000-7400 | 7300-7700 |

Hcb(kA/m) | 199-263 | 302-374 | 390-454 | 405-470 | 421-484 | 413-477 | 430-493 | 366-430 |

Hcb(kOe) | 2.5-3.3 | 3.8-4.7 | 4.9-5.7 | 5.1-5.9 | 5.3-6.1 | 5.2-6.0 | 5.4-6.2 | 4.6-5.4 |

Hcj (kA/m) | 477-597 | 597-796 | 636-796 | 955-1114 | 915-1034 | 636-796 | 636-796 | 517-637 |

Hcj(kOe) | 6.0-7.5 | 7.5-10.0 | 8.0-10.0 | 12.0-14.0 | 11.5-13.0 | 8.0-10.0 | 8.0-10.0 | 6.5-8.0 |

(BH)max (kJ/m 3) | 24-32 | 44-53.6 | 60-68 | 65.6-72 | 72-80 | 76-84 | 80-88 | 84-92 |

(BH)max (MGOe) | 3.0-4.0 | 5.5-7.0 | 8.0-9.5 | 8.2-9.0 | 9.0-10.0 | 9.5-10.5 | 10.0-11.0 | 10.5-11.5 |

Tw/ ℃ | 120 | 120 | 120 | 160 | 160 | 120 | 120 | 110 |

Surface Protection Available of plastic bonded neodymium magnets

| Type of Coating | Coating Thickness | Anticorrosive ability | Adhesion Force | Note |

| Electrophoresis | 10-30um | Strong | Strong | Mount Point |

| Spray Coating | 5-20um | Normal | Normal | Restriction of Specification |

| Impregnation | 1-3um | Weak | Weak | / |

| Parylene | 5-20um | Strong | Strong | High Cost |

Examples of surface Flux Density Distribution of plastic bonded ndfeb magnets

The factory has over 15 years experience on manufacturing and technology on the plastic bonded ndfeb magnets. With its own molding workshop, the factory can accomplish entire production process in-house from molding design, manufacturing and maintenance. The plant has obtained automatic production with rigorous Japanese-type management and precise equipments imported.